Paraphernalia

A whole world surrounds the manufacturing and wearing of gloves. This section shows some of the ‘can’t live without essentials’ of the wearer 'A lady's trappings' and ‘needs’ of the manufacturer 'A Manufacturer's musts'.

A lady's trappings

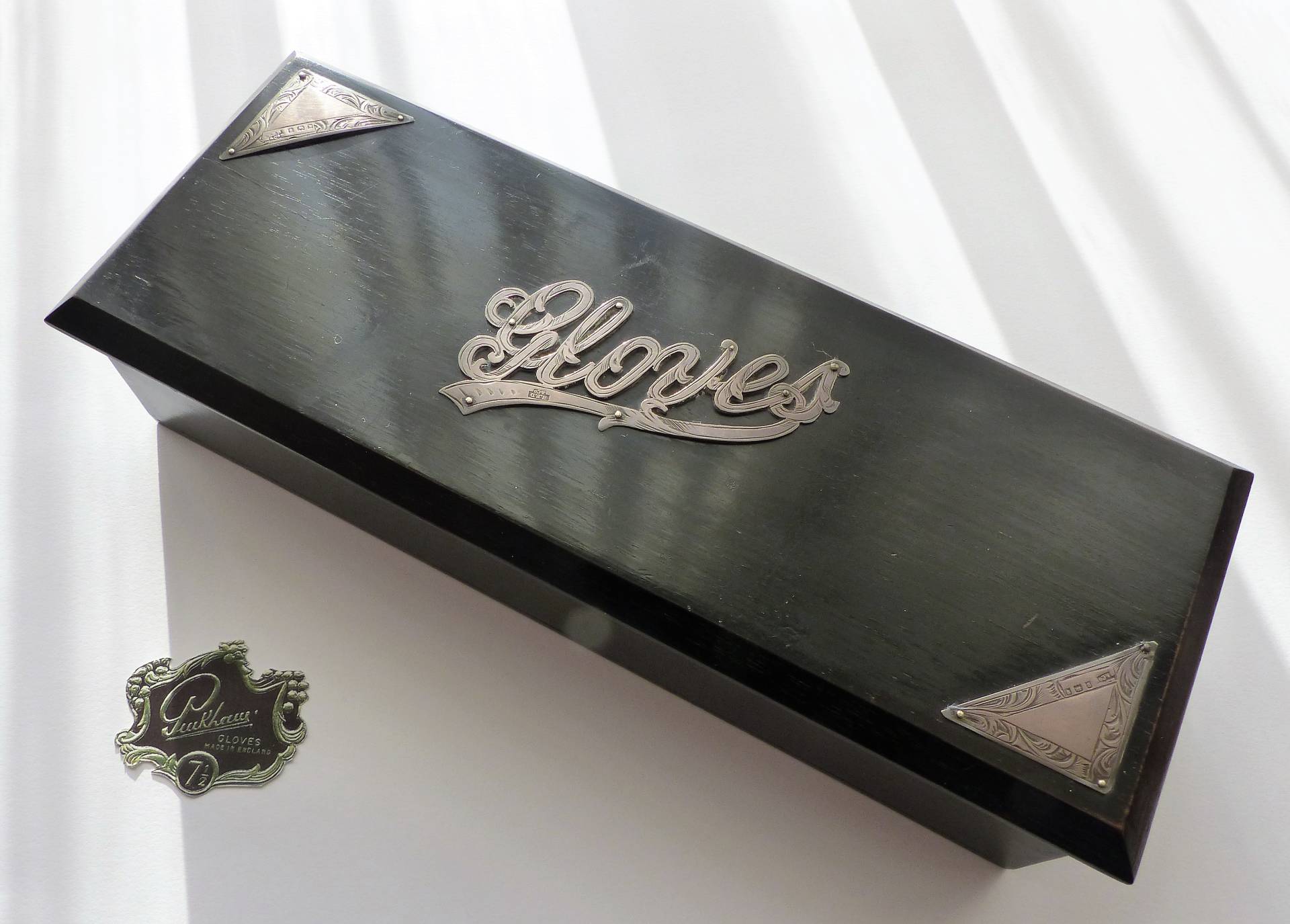

Glove storage

With many pairs of gloves there was always a need for a lady to find somewhere to keep her precious fashion statement. Glove boxes were made in abundance from humble box wood to expensively decorated wonderments. As decorative items they would find their way onto the dressing table to match some of the other glove 'accessories'. Not only did boxes provide safe haven for gloves, glove bags were also widely used and very often made by the lady to show off her sewing skills.

Glove clips

No lady in the 1940s and 1950s would be without her glove clip. Simply pop your gloves into the holder and then secure the chain to your handbag. Never a lost glove.

Royal glove clips

This elegant clip is one of many that was presented to each of the ladies who attended The Queen's coronation in 1953. If only it could tell us its story.

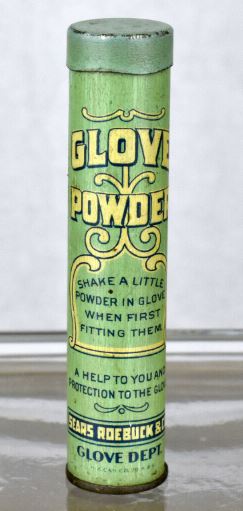

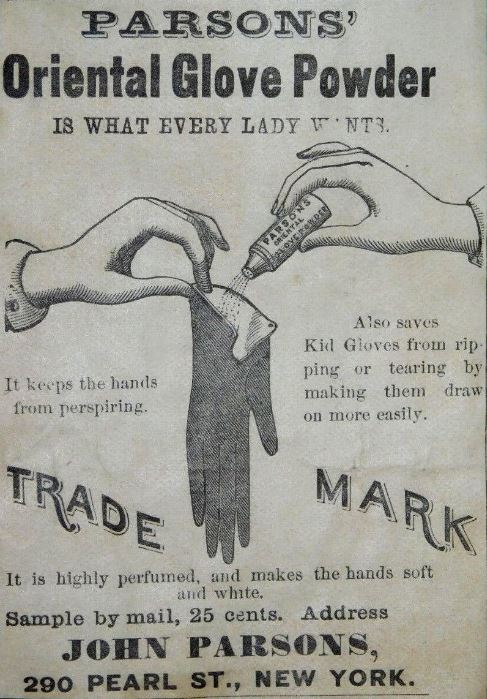

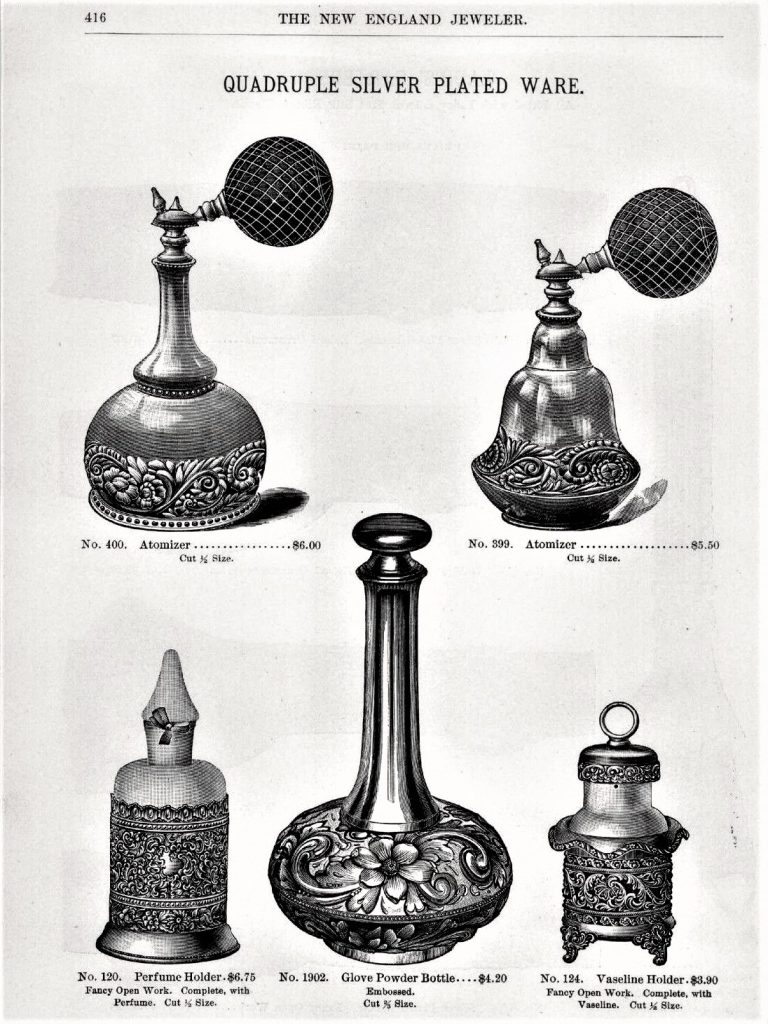

Glove powder and glove powderers

Especially with tight fitting leather gloves glove powder was a must have. No lady’s dressing table would be complete without a glove powderer. A fine powder which was either French chalk or talcum was applied to the inside of each glove so that the wearer’s hand would slide easily into the garment and as the saying goes “fit like a glove”. To enable the powder to be applied a glove powderer was used. As can be seen from the photographs below these took many forms and were a focus for the luxury dressing table set maker.

A brooch to shine close to your heart

Each a reminder of the skill of both the jeweller and the glove maker.

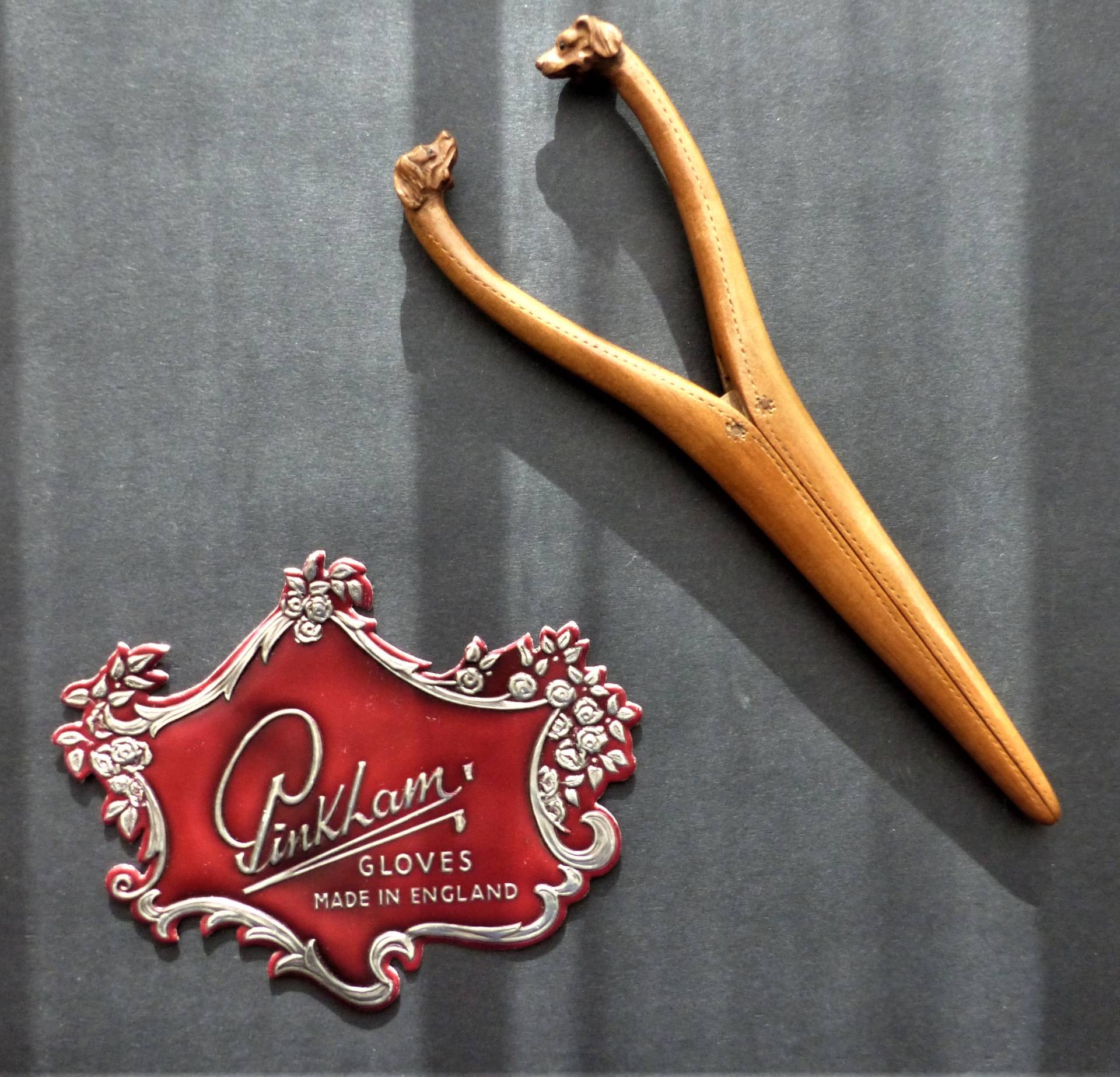

Glove stretchers

So every lady’s maid would have a pair of glove stretchers which were inserted into the fingers of each glove and opened to stretch it back into its original shape without any creases. In some cases these would creep onto the dressing table which meant they could become a thing of beauty.

By the very nature of where they are worn gloves get dirty. Indeed on many occasions gloves were worn by ladies specifically to stop their hands getting dirty. So a dirty glove needs to be cleaned. With fabric gloves as is explained in the Packing & Labels section they are simply washed and then ironed. Leather gloves too are washed but when dry the leather needs to be stretched.

Buttons and bows

Fiddly buttons on evening gloves, sometimes as many as six on each glove could be very very difficult to do up. As with buttons on boots a hook came to the rescue; with a much smaller hook and shaft than a boot hook a glove hook worked on the same principle. The hook was put through the button hole and once it is around the button it was pulled back through the hole. What could be easier?

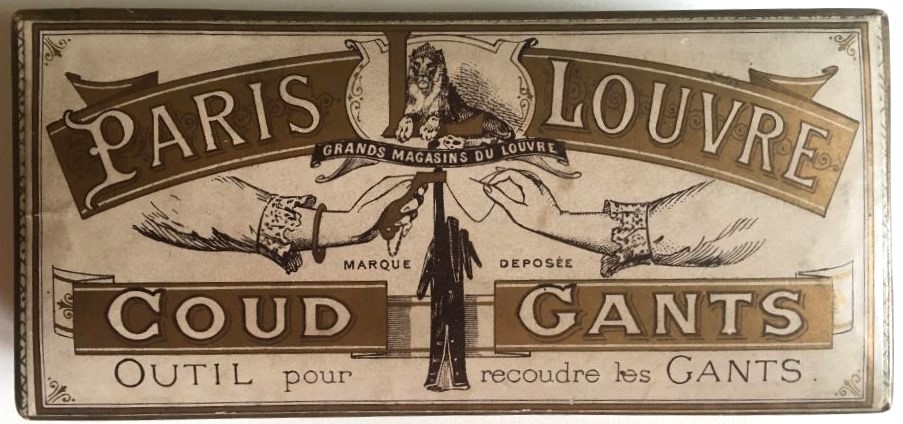

Perish the thought - Glove repairs!!

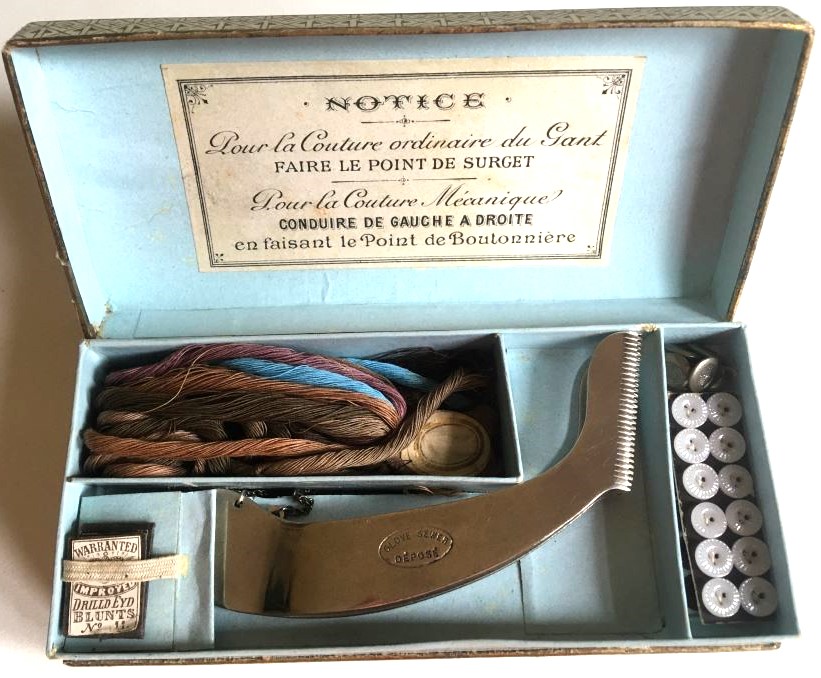

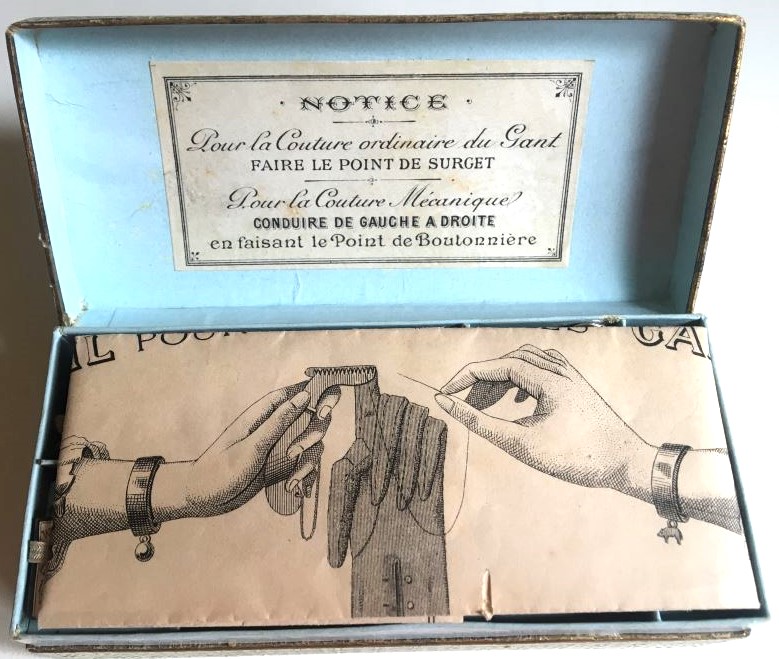

When times were hard and new gloves might have been beyond the wearer’s budget a hole in a glove could be darned to give the gloves another lease of life, enter The Glove Mending Kit.

This very unusual French ‘mend your gloves’ glove repair kit dates from the end of the 19th to the beginning of the 20th century when there was an emphasis on detail and quality. It was found in The Netherlands and is in pristine ‘unused’ condition.

It consists of what looks like tiny glass buttons, thread and a needle pack about 1cm square, instructions and most intriguingly a ‘glove sewer’.

This is a device which is clamped onto the glove whilst being sewn and enables the sewer to regulate the spacing of the stitches consistently.

It also came with a small wooden darning tool for the glove fingers (like the one you have pictured above), though this wasn’t part of the original contents of the kit.

It was flying the flag for a greener textile industry over a hundred years ago. Instead of throwing away a worn glove the focus was on repairing it and giving it a new lease of life.

As with the glove hook to the rescue came a glove darner. Inserted into the ‘holy’ finger it gave the repairer a firm base to effect the repair.

This darner was found in the repair kit.

A manufacturer's musts

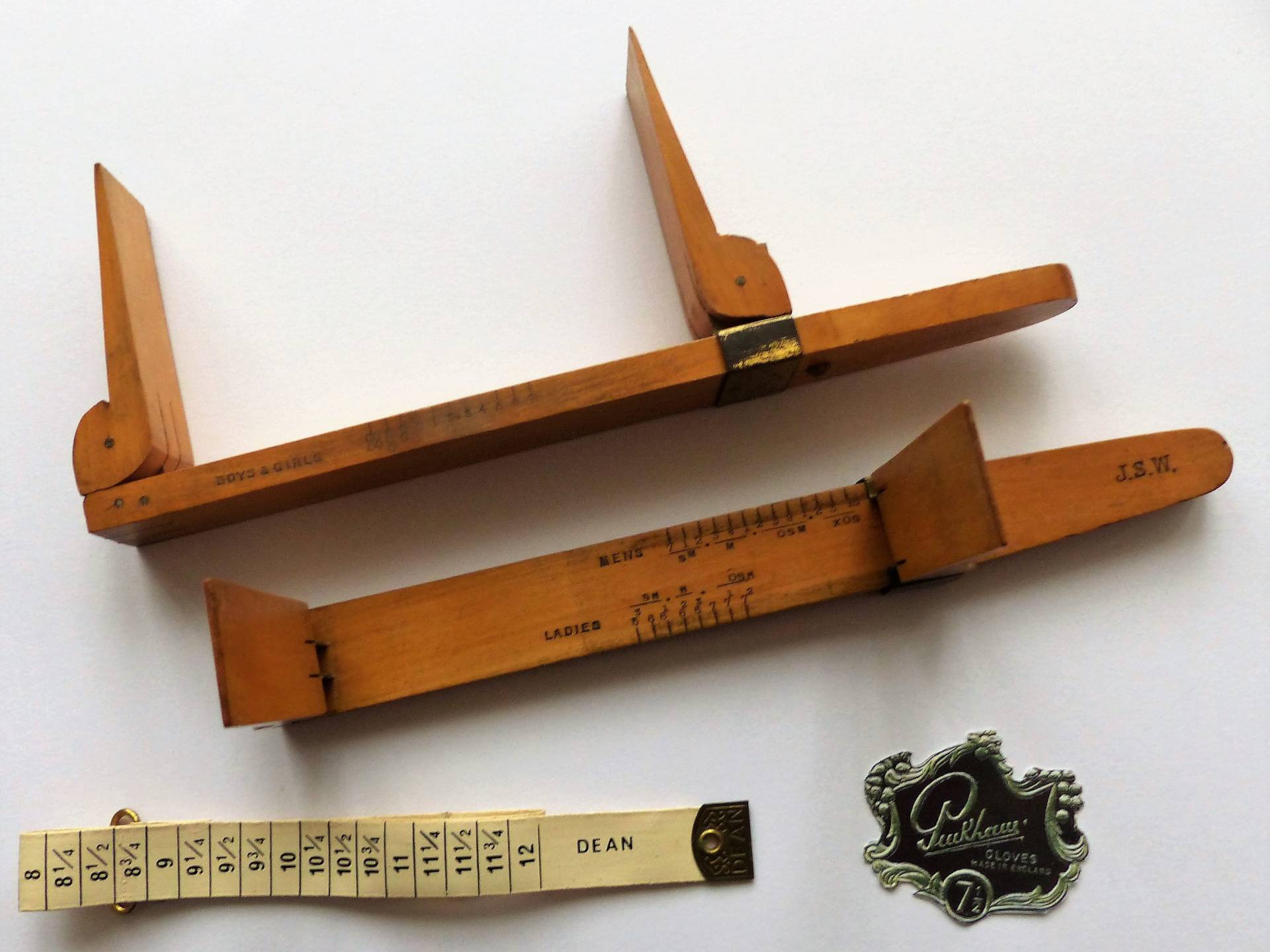

Measure twice fit once

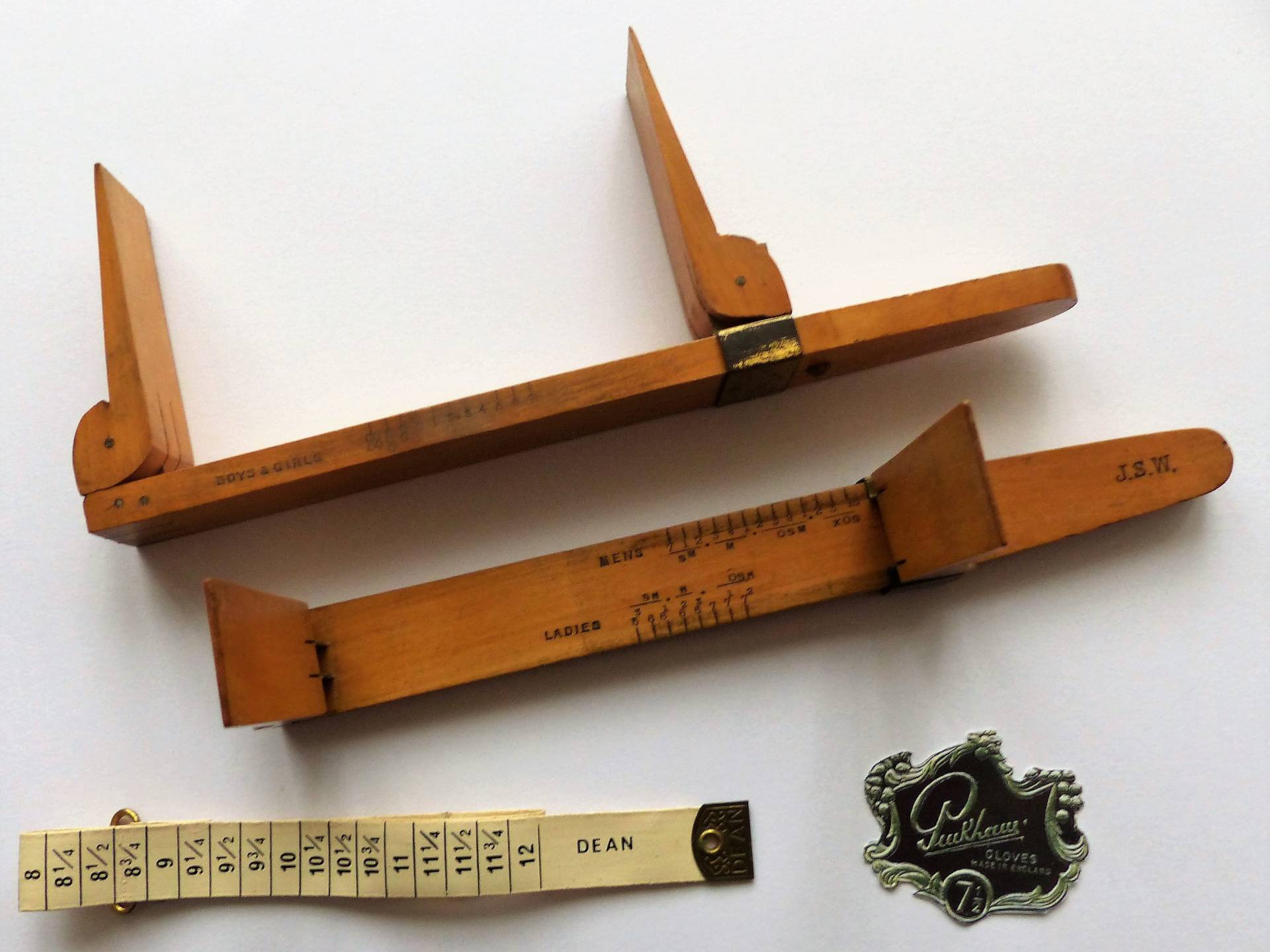

Size matters and to ensure that a fine pair of gloves fitted ‘like a glove’ there was a fundamental need to accurately establish the size of the wearer's hand. Below are two devices for achieving this. They were mainly used in retailer’s shops to measure the wearer’s hand at the counter although many a good glove maker would be able to tell the exact size of a wearer's hand by sight.

A cut above the rest

Cutting fabric was one of the key elements of glove manufacturing. Fabric would be layered and then cut with metal pattern presses cutting through the fabric rather like a cider press. These metal patterns would be kept in fire proof safes when not in use for if they were destroyed manufacturing would be halted. In addition high quality shears were used to cut fabrics and leathers during manufacture. The pair seen below is similar to those used at the Pinkham factories. As with the sewing machines a team of mechanics kept them in perfect working condition.

Quality that's obvious

Quality was everyone’s priority and quality control was the most important part of production throughout all stages. Once the gloves had been finished and before going for ironing and packing careful attention would be given to the stitching on each glove. Most gloves were stitched by machine and some would be finished by hand and the quality inspectors would look for the stitching quality using a thread counter. As can be seen from the picture below these are magnifying glasses which were placed over the stitching and the number of stitches over a set length of the seam would be checked.

Wooden factory stretchers

These three piece wooden ‘hands’ in all sizes were used to stretch leather gloves into shape prior to packing.

Singer guard

This cast iron guard is a left over from the Victorian age of ornamental industrial machinery. Used to guard the machinist sewing area, here in the 1920s they can be seen alongside each machine in The National Glove Company's Witham factory.

Button up

From the early days most machine sewing was done using a foot operated treadle machine which was surpassed by electric sewing machines. However button holes would have been sewn using a very fine hand operated sewing machine. Good eyesight and nimble hands were musts.

Email your stories of Pinkham Gloves

nickpinkham@pinkhamgloves.co.uk