Many people over the years have been associated with the Pinkham's glove manufacturing and the recollections from some of those who worked in the business over many years form a vivid picture of everyday life in the company. Here are those stories straight from 'the horses mouth'

Paul Gillett

Leather Salesman for C. W. Pittard & Co. Ltd.

December 2024

Paul recalls

I first visited the Pinkham glove factory in Stanley, Co. Durham as a young trainee salesman in 1964, two years before the company closed. It was a very modern factory, having been opened in 1959.

I had joined Pittards in 1961, as a “junior trainee export sales executive “, having just left University. I was given two years training in the manufacture of leather and I also went to a glove factory in Munich to study glove manufacture and the owner’s son did an exchange visit to our Yeovil factory to study leather manufacture, although they did have an associated tannery in Munich tanning deerskin for Lederhosen.

After my training, I visited some of our customers in the UK to get my first taste of selling and no doubt, for Pittards to assess my “performance”.

My first visit to Pinkham’s Stanley factory was the furthest north I had travelled, having driven from Yeovil in Somerset in a Ford Anglia with no heater and certainly no radio for entertainment during the 8 plus hours journey.

I must confess that I cannot recollect the names of the individuals whom I met at the factory*. We sold some quantities of gloving leather to them at that time.

Sadly the company closed down in 1966, due to increasing foreign competition. This trend has continued over the years and I believe there is now only one leather glove factory still in business in England.

Sadly, Pittards also closed down on September 5th 2023, having been established in 1840, so six generations of the Pittard family had been involved in the business, but no longer had ownership of it after it grew into a large group of tanneries as a listed company.

The book, entitled W. PINKHAM & SON LTD. The Story of Pinkham Gloves is a fascinating account of the Pinkham family’s success in building a very large company from small beginnings in the 1880s and over the following 80 years or so.

An added distinction for the company was that Leslie Pinkham became Master of the Worshipful Company of Glovers of London, a fitting tribute to the company’s position in the glove making industry.

*At the time David Pattison was the factory manager working alongside Richard Pinkham and Geoff Ellis the production manager all of whom would have been involved with the purchasing of raw materials.

Ann Gill

October 2024

Ann Gill has been in touch and has recognised her mother in one of the photos of the opening of the Stanley factory.

Ann says

“My mam is in the photo, she is in the back row with the straight cut fringe. Her name was Barbara Sayers.

She worked there when the factory was opened in June 1959 when she would have been nineteen. She left two years later to start a family.”

Barbara is seen here in the back row with Lord Lawson the local MP at the opening of the new factory at Stanley on June 18th 1959.

The company was quoted in the local press at the time as having opened the factory largely due to the “faith of the directors in the quality and skill of the work of the Stanley girls” and of course Barbara was one of those highly skilled girls.

Sylvia Irene Clark (née Lloyd)

January 2021

Sylvia’s daughter Linda recounts the story of her mother Sylvia Irene Clark (née Lloyd) who worked at the Dagenham factory with a friend Margaret Clark. On one occasion there was a works outing to see a show at the London Palladium and Margaret asked Sylvia if she would like to go to the show on a blind date with Margaret’s brother Alan Clark. The rest as the saying goes is history.

Ann Foster

November 2019

I was born in 1947 and lived in a small village called Catchgate, County Durham, not far from Stanley.

I remember my mother Audrey Johnson trying to make ends meet in the late 1950s and early 1960s by sewing gloves by hand at home for the Pinkham factory.

We were a large family; I was the eldest and so had to help out with whatever was going on to make ends meet. Those days miners had a ton of coal tipped outside their houses, she would shovel it into coal-house to get buckets of coal to keep the family warm. But I remember her sewing gloves well into the night and sometimes I would help her.She died in 2007 in her eighties.

May King

December 2011

Extract from Janet Gyford’s book The History of Witham

May King, born 1898 was talking about Mr Pinkham’s glove factory, where she worked for forty two years.

Oh yes and Christmas time we used to have a big Christmas tree in the factory in the space and he used to put a little present on for everyone of us and he used to dress up as Grandfather Christmas and he used to call out the names and take them off the tree and that was very nice that were. That was the last day before the Christmas holiday you see. They used to be goo up there. I used to enjoy that. But I dare say they don’t do nothing like that now do they?

Courtesy of Janet Gyford janetgyford.com Many thanks.

Margaret Matthias

November 2019

I worked in the pressing end for about a year.

They asked for volunteers to do a stock check one Saturday morning! My friend Clare Loan and I said we would! As I was quite agile I got up to call stock numbers down to Clare. I perched on a small window sill with iron bars. Suddenly, the boss appeared, with a policeman. We thought it must be bad news for her or myself. Boss said “Margaret, are you comfortable up there?” I had inadvertently triggered the alarm. I was the butt of jokes for quite some time!!

Marjorie Streibelt (née Ainsworth)

August 2019

I started working at the Pinkham Glove factory in Park Road South Moor in 1955 with my twin sister Joan Ainsworth. My older sister Kathleen Ainsworth also worked there, and it was when I went to the factory after school one day to pick up her wages and saw the girls working and singing that I thought it would be wonderful to work there. I was a piqué worker* and my sisters were on the brosser machine**

Even today my sisters remember that it was family friendly place to work.

When Joan married she moved about ten miles away but worked from home. Mr Patterson would take the work to her at her home and then pick it up again - business must have been good at that time.

There was always music playing in the factory. The manager was Mr Patterson. He was very nice but a bit strict. In winter when it was cold he arranged hot oxo for the workers. At lunch time we often played table tennis in the canteen. It was there that I met my husband Hans Streibelt, I invited him to a game and we have been together since; 58 years married thanks to Pinkhams.

Having worked at the Witham factory Hans transferred to South Moor in 1959 to work with another four German lads Gerhart Muller, Rudolf Beuter Manfred Binder and Godfried ?. (Gerhart was from Halberstadt, Godfried from Hamburg, Rudolph from Balingen and Hans and Manfred from Metzingen near Stuttgart.

They were all fully trained when they came to England.) Mr Vic Stokes was our manager at that time and he was from Tiverton in Devon. We called to see him before he died when we were on holiday. He cried when he saw Hans and said, "One of my boys." He was a very nice man.

Happy Memories”

Marjorie Streibelt

It is interesting to note that Richard Pinkham had trained in a German glove factory in the 1930s before working the Pinkham business.. Although it is not known which company he was with in Germany it is thought to have been in Saxony.

* piqué is a type of machine stitching where the edges of leather are overlapped so that only one edge shows. Mainly used for thinner ladies gloves where the glove needs to fit tightly.

** brosser stitching also called a whipstitch is an overseam stitch where the leather is stitched edge to edge but covered by overstitching so the edges do not show.

Carole Turner

August 2016

Carole tells of her father and his two sisters who all worked at the Witham factory. Geoff Ellis became senior cutter having joined the business after serving in the second world war. In 1959 he moved to the new factory in Stanley Co. Durham to manage the cutting team in the new factory. Both his sisters had started working at the Witham factory in 1926 when Agnes was 14 and Ethel was 24. The picture below shows the clock that was given to Agnes in 1949 on the occasion of the company’s fiftieth anniversary.

Geoff Ellis around 1960 at the Stanley County Durham factory preparing layers of cotton fabric for cutting.

Geoff Ellis (second from the right) at a Christmas party at the Stanley County Durham factory in the 1960s. The man wearing the bow tie was the factory manager David Pattison who had managed a kilt factory.

Agnes Ellis

AGNES ELLIS'S CLOCK

The clock that was given to her on the company's fiftieth anniversary in 1949.

Ann Brignull

May 2019

Ann Brignull recounts:

My mum, Florence Watson made up Pinkhams gloves at home from around 1953 to 1960 and she would go and fetch them from Mrs. Rich who lived in Cressing Road, Braintree.

She would have a bundle of twelve gloves a week sitting every evening stitching away but if they were black she would have to do them in the afternoon.

I think she was paid 1 shilling (5p in today’s money) for the dozen and if they were beaded she earned a bit more. She often pricked her fingers and worry she would get blood on the gloves.

Thank goodness life has changed.

Debbie Byam

July 2016

Debbie Byam recounts as a child visiting the Witham factory with her mother:

I can remember the factory well as I visited it with my mother in the 1950s and 60s when I was a young girl.

My mother, Mrs. Payne used to hand stitch the tops of the gloves at our home, we used to catch the bus from our home at Cressing, getting off at the Witham railway station and deliver the gloves to the factory office nearby and collect the next batch.

I don't know how much she was paid, but I remember the gloves were checked before she collected her pay.

Daphne Jones

February 2018

Daphne Jones recalls the work that her mother Ida Drabble did for the company in the 1950s:

I spent my childhood in Colchester, Essex. In the 1950s a representative from W.Pinkham & Sons Witham used to come to our house on a particular day and deliver a box of pre-cut glove parts from the factory to my mother Ida Drabble.

She would then separate these into batches to be given out to women outworkers who would collect them from her to be stitched together in their own homes.

They would return the completed gloves to my mother who would arrange for their return to Pinkham's, probably via the same representative.

I remember these as felt gloves, usually in dark colours, with the seams facing outwards, and neat visible stitching in fairly thick thread – part of the design. There were neat rows of stitches on the backs of the gloves

My mother must have received some training in this work as I remember that quite a number of women came, sometimes staying a while for instruction on stitching by my mother.

I can’t remember if she dealt with payments for this piece work. Similarly I don’t know whether she delivered the completed gloves to Witham, or if they were collected from her. She did not drive in those days.

I have a very, very hazy recollection of visiting the Witham factory with her on one occasion, but I guess that generally the glove parts were delivered to her, and the completed gloves collected.

This is a distant memory for me. Sorry it is a bit vague, but I was less than ten years old at the time. I have, however, much enjoyed this trip down memory lane, which I am delighted to share.

Daphne Jones

Eileen Cowell (née Jennings)

August 2016

Eileen Cowell tells of her time working at the Witham factory between 1946 and 1958.

Eileen’s brother Aston Jennings and her sisters Barbara, Marie, and Shelia had been working at the factory for sometime and one day in 1946 she was walking past the factory on her way to the cinema and decided as she was passing to pop in and see if they had any jobs. She was met by Herbert Keeble and after a short discussion he offered her a job on the spot and asked “when would you like to start” and she replied “now”. Mr. Keeble suggested that she had a week’s holiday and then start.

Eileen was taken under the wing of Mrs Turner one of the machinist trainers and it was soon clear that Eileen had a talent for machining gloves and she quickly progressed and in no time was promoted to become a trainer teaching six girls at a time and only when she said they were competent and good enough were they allowed to work on their own.

Not only did Eileen teach the new girls she prided herself in sewing up eight dozed pairs (192) gloves each day and was not at all happy if she fell short of this number.

On one occasion the belt came off her sewing machine putting it out of action, she reported it to Vic Keeble (Herbert Keeble’s brother) one of the factory mechanics and after waiting for him to turn up and look at it she ended up fixing it herself after which it worked perfectly and she hit her daily target.

With advent of the use of Nylon for making gloves Eileen worked on some of the trial batches to evaluate how the fabric performed when being machined. She discovered that the sewing needles used for machining cotton fabric were too thick and as a result ripped the nylon, she insisted that thinner needles should be used and that produced perfect Nylon gloves with no flaws.

This was just as well because the gloves faced very close quality inspect once they left Eileen’s machine. She recounts that the two quality inspectors at the time Mrs Balls and Mrs Dobson always wanted to inspect Eileen’s work as they knew there would be nothing to have to look out for.

Let's party

Here Eileen is with some of her workmates sometime in the 1950's. She is in the second row from the back seventh from the right. Given the winter coats it may have been a Christmas party. It certainly looks as though everyone is in party mood.

Please get in touch if you recognise any one in the photo email: nickpinkham@pinkhamgloves.co.uk

Veronica and Leslie Cook

December 9th 2015

From The Braintree & Witham Times

Veronica and Leslie Cook, who got together after a snowball fight in 1939 celebrate 70 years of marriage.

Their son Royston, 69 said:

There are not many who get to 70 years, they have done well over the years.

You couldn't meet a closer couple. They are never without each other. If you see one you see the other.

The couple moved to Church Street in Witham in 1948 and then lived in Ebeneezer Close in 1964.

Les worked in the Ford factory in Dagenham before taking a job at the Crittal's factory in Silver End. He worked there for forty years, retiring in 1989.

Veronica worked in the famous Pinkham's glove factory in Witham, which made garments for the Royal Family.

They settled in their current home in Shortridge Court, Witham in 2000

They had two sons, Royston, 69, and Melvyn 64, and now have eight grandchildren and 12 great-grandchildren.

The pair celebrated their milestone with a party at the Rivenhall Oaks Golf Centre.

Mary Pinkham

April 2016

THE ROMANCE OF W PINKHAM & SON LTD

The West Country had always been the home of leather and glove making. Back in the latter part of the nineteenth century there was a skilled leather glove cutter called William Pinkham (25/12/1861 – 18/10/1938) living and working in Great Torrington in Devon. Rebecca Fowler (14/5/1864 – 7/12/1952) was an out-worker who completed the making up of the gloves and they were married on March 13th 1884 and subsequently went on to have two children: Leslie (24/12/1890 – 3/9/1965) known as Bert and Lilian (b5/1/1886) known as Dinah, she married a Scotsman Wilson Dawson and had two daughters.

On September 4th 1915 Bert married Elsie Mansfield and had four children. William was keen on politics and his interest meant he was a member of the Liberal Party. At the turn of the century, around 1900 he was appointed Liberal party agent which meant moving to Witham in Essex.On arrival in Witham in 1905 they rented a small house in Albert Road opposite the railway station and had begun making gloves.

Soon Rebecca took in young ladies to help her with all the sewing and in a short time the business grew and they took over the house next door to house the workers. In 1912 a small factory was built nearby and local people worked there sometimes many people from the same family.

As the business grew William, following a visit to Dagenham where Ford were building cars, had the vision that where there was a large male working population there would be a female working population that needed jobs. (Women had much better sewing skills than men) and so a factory was built 1933 in Dagenham employing about fifty local people. Dagenham had the large Ford motor works which meant there was a large working population. The manageress was a Miss Keeble whose family had worked at the Witham factory over a number of years. Walter Keeble was the factory manager and two of his relatives were highly skilled sewing machine engineers. Another family involved with the Witham factory was the Otley family and worked there for many years.

Each year there would be a staff Christmas party and William’s son Leslie (Bert) would dress up as Father Christmas and give out Christmas presents and in the summer there would be a Summer Works Outing, usually to Clacton.

The factories grew in size and numbers of employees and the reliance on out workers increased too especially in towns near to Witham, Maldon, Braintree and Silver End. Cut gloves would be delivered to an agent ‘in the field’ who would distribute the work to the out workers in their homes. Some had their own sewing machines and others worked on the hand sewn gloves. The finished gloves would be collected either weekly or fortnightly. I remember that on one occasion I offered to take a consignment to Maldon, I had to drive an Austin Seven (Baby Austin). I was unaware how to engage reverse gear, it was a complicated system of various gear levers. So I had to find a tree to circle so that I was headed in the right direction for home - never again!!

All the cutting was done at the Witham factory and many of the cut gloves were taken in a very large van to the Dagenham factory to be sewn (made up) and then the completed gloves were returned to the Witham factory to be pressed, finished and packed and then dispatched all around the world to places such as America, Canada, New Zealand and Europe.

Nottingham was the centre of glove fabric manufacturing and in particular a fabric called Helanca (a trade name). It was specifically suited to evening gloves which until then were usually made of fine white kid leather which were difficult to put on and had to be worked onto the hand slowly. Helanca was stretchy and gloves made of it were easy to put on and take off. In many ways it revolutionised glove design and manufacturing.

More competition! Fabrics could be made in and around Nottingham shipped to Hong Kong and elsewhere around the world made up into gloves and sold in the UK at lower prices than W Pinkham and Son - very sad.

Mary Pinkham (wife of John Pinkham)

1922 - 2018

Margaret Bell

November 2017

Margaret Bell recalls working at both South Moor and Stanley factories in the 1950s and 1960's along with her Sister who sadly died last year.

I was a piece worker putting thumbs in gloves. We were paid one shilling and threepence per dozen pair. They were wrapped in bundles. We produced a lot of gloves for Marks and Spencer and they were done perfectly. The Boss was Mr Pattison and I began working at the Park Road factory in South Moor and later moved to the Anthony Street factory in Stanley.

My time there was very happy, part of a big, happy family. The music( all 60's music) was always playing and we used to sing along to the likes of Buddy Holly and Marty Wild. We used to work with rollers in ( we used the empty thread reels ) We used to get ready and go out to the dances. Every Friday was fish and chip day. There was a standing order at the fish shop. Oh Happy Days!!

Joan Hall (née Greener)

March 2018

Joan Hall (née Greener) worked at both the South Moor and the Stanley factories from 1953 until 1963. Having left school on the Friday she started work in the South Moor factory which was above the Co-op on the Monday. She was part of a team of some thirty machinists and worked Monday to Friday and describes it as a happy place to work. Following her initial training she worked on making up fabric gloves and was able to sew three dozen pairs (seventy two) of gloves a day. Once she had finished the machining the gloves would be inspected by one of the quality supervisors who were very picky and would return any that were not up to standard. It was certainly a family affair with her sister Margaret Greener working as a machinist too and her younger brother Alan Greener starting as an apprentice mechanic looking after the machines. A hard working team needs to be well fed and Joan recalls the factory canteen which produced meals every day and was run single handed by Prudy Cuthbert.

She was at the opening of the new Stanley factory on June 18th 1959 and can be seen in the picture with Lord Lawson who ‘cut the ribbon’ at the opening ceremony.

Gareth Foster

November 2018

Gareth Foster from South Moor writes:

I can remember In the late 1980s and early 1990s going in with my friends on a regular basis and explore the old Co-op building in South Moor where the Pinkham glove factory was upstairs.

Even though the building had been empty and derelict for a lot of years there was still the odd pieces from the Pinkham glove factory lying about like old adverts and if I remember correctly some old paperwork and some old wooden glove model hands some glove boxes and materials and some cardboard boxes for delivery lying about upstairs. It was crazy it was still there even after moving to the new factory in Stanley all those years before.

Even downstairs on the ground level all the Co-op woodwork was still on the walls and around the door frames and on the front of the building. The four different department signs above the doors were still underneath the wooden shutters outside, crazy!! The basement of that building was absolutely massive and went underneath the road and pavement to the other side of the road, it was unreal.

Then in 1996 the building got demolished and all the stuff that was in that building there just got put in a skip.

The Pinkham Glove production was on the first floor

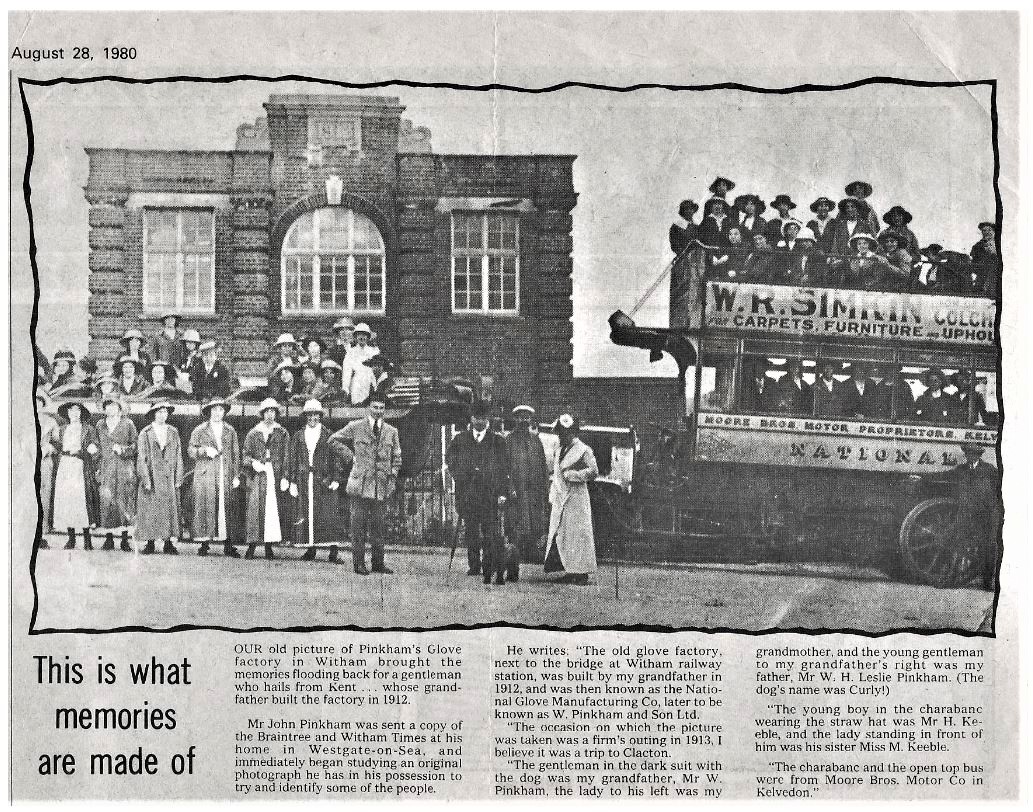

This is what memories are made of...

August 1980

Below is an article from The Braintree and Witham Times in 1980 in which John Pinkham identifies a number of the people.

Email your stories of Pinkham Gloves

nickpinkham@pinkhamgloves.co.uk